Choosing the Right TreeHugger Tree Shear

Picking the best TreeHugger model starts with your machine platform and its hydraulics. This guide walks you through the key checks, compares the TH B8 / TH B10 / TH B12-5 and TH R8 / TH R10 / TH R12-5 families, and suggests accessories by job type — so you can spec with confidence and avoid trial and error.

Quick Spec Checklist

Enhance your setup with Exator’s modular accessories:

Machine Type & Size

- Excavator operating weight (t) or loader/telehandler class

- Skid steer ROC (Rated Operating Capacity) and hydraulic package

Hydraulics

- Available flow (GPM / l/min) and pressure (psi / bar) at the attachment

- 1 vs. 2 auxiliary circuits; need for a 6/2 valve for multi-function control

Work Profile

- Typical stem diameter

- Job type: selective thinning, Right of Way (ROW) / roadside clearing, land clearing, biomass, urban lots

Handling

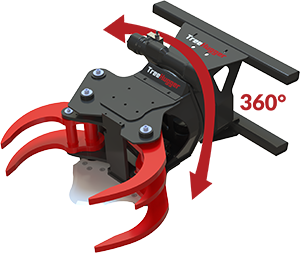

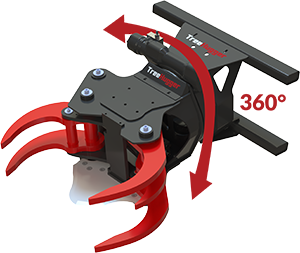

- Need for 360° continuous rotation (tight sites, stacking, exact placement)

Not sure about your numbers? Send your machine model and use case — we’ll size it for you.

Model Guide

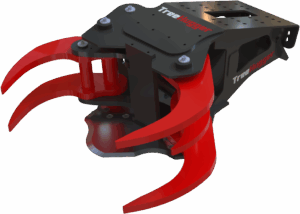

Excavators — B-Series (Basic)

TH B8 Tree shear

Excavators 1.8–5 t

Key features: eBoost®

TH B10 Tree shear

Excavators 5–12 t

Key features: eBoost®

TH B12-5 Tree shear

Excavators 12–20 t

Key features: eBoost®

Tip: If your jobs demand frequent placement, stacking, or work in tight corridors, prioritize R-Series models with 360° rotation.

Excavators, Loaders, Telehandlers & Skid Steers — R-Series (Rotation)

TH R8 Tree shear

Excavators 3–5 t

Key features: eBoost®, 360° rotation

TH R10 Tree shear

Excavators 5–12 t

Key features: eBoost®, 360° rotation

TH R12-5 Tree shear

Excavators 12–20 t

Key features: eBoost®, 360° rotation

TH R8X Tree Shear

Loaders: 1,3-2,5 t

Skid steer / Telehandler lift cap. 992 lbs

Key features: 360° Rotation system, eBoost®, 8 in cutting diameter

TH R10X Tree shear

Loaders: 3-6 t

Skid steer / Telehandler lift cap. 1984 lbs

Key features: 360° Rotation system, eBoost®, 10 in cutting diameter

TH R12-5X Tree shear

Loaders: 6-21 t

Skid steer / Telehandler lift cap. 2870 lbs

Key features: 360° Rotation system, eBoost®, 12,5 in cutting diameter

Hydraulics: What Really Matters

Flow and pressure drive cycle speed and cutting force. eBoost® delivers up to 2× faster cycles without power loss — even on lower-flow, lower-pressure machines.

Auxiliary circuits: If you need simultaneous grip + rotation or collector control, add a 6/2 Valve.

Hose management: 360° rotation systems benefit from hose-through routing to prevent twisting.

Compatible Accessories

Enhance your setup with Exator’s modular accessories:

Collector

increase work efficiency

Cable Control

wired operation

Felling Support

for large or leaning trees

Radio Control

wireless operation

FAQ (Quick Answers)

Match machine class first (weight / ROC), then verify flow & pressure at the coupler, and finally check your maximum stem diameter.

If you stack or place material frequently — or work in tight ROW / urban areas — 360° rotation saves time and machine movements

Yes. With eBoost®, many lower-flow carriers achieve fast cycles without power loss.

Next Steps

Ready to find your perfect match? Tell us your machine and job type — we’ll recommend the ideal TreeHugger model for your needs.